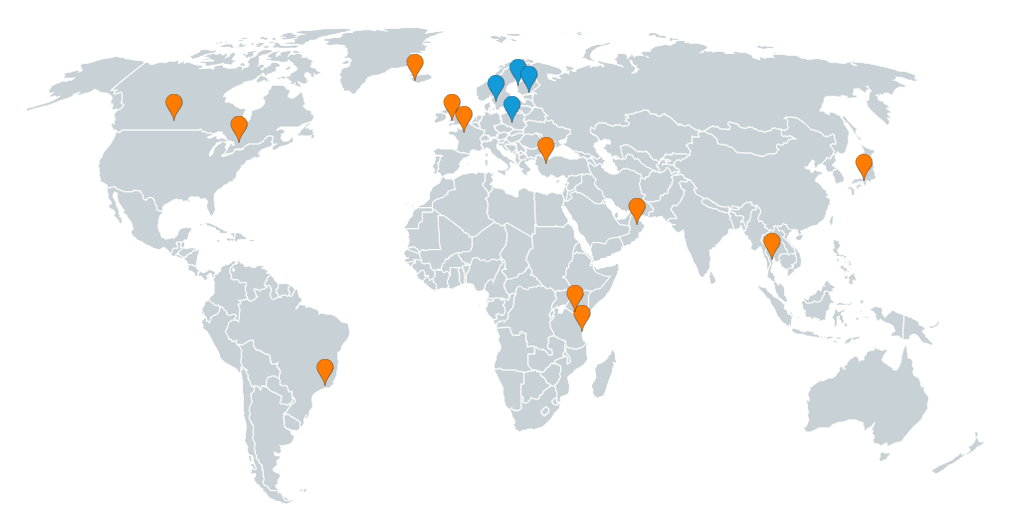

Weholite Technology was developed in 1983 and has since transformed the global market for large diameter plastic pipes. During that time, Uponor Infra Technology has established a network of successful licensees across the World.

ABOUT UPONOR INFRA WEHOLITE TECHNOLOGY

Behind all the best brands, there is a strong team of creative and innovative people that keep driving it onwards to new heights. The team at Uponor Infra Weholite Technology is no different. Weholite production machinery has long been regarded as the best in class. It is designed and made in Finland using the highest quality components and to the highest standards Worldwide.

The machinery carries the CE mark and brings with it the quality, reliability and trust that that certification entails. Combine this with Finnish ingenuity and reputation for advanced engineering and you can rest assured in the fact that with Uponor Infra Technology as your partner, you are entering a new dimension.

JOINING THE WEHOLITE FAMILY

Becoming a Weholite licensee can transform your business. Some of our licensees have Weholite as their main business offering while for others it is complimentary to their core business.

Joining the family provides access to an inclusive network of businesses across the globe that are manufacturing Weholite for a variety of different applications. A culture of knowledge transfer and best practices means that new ideas are shared, and support is always available.

JOINING THE WEHOLITE FAMILY

The Weholite pipe production line forms the main part of the licensing agreement and along with equipment for the production of Wehopanels, fittings, joints, field jointing and quality control provides a complete production set-up. The range of equipment can be tailor-made to suit your needs.

Production support from Uponor Infra and other licensees is always available, and the licensing agreement includes support with production set-up, personnel training, different applications and access to continuous production development.

As a Weholite licensee you can use the Weholite trademark, references, internal product standards and manuals, calculation software, product development, quality control and marketing material developed by the wider Weholite family.

The territory in which you operate will be exclusive and defined as part of the agreement.

WEHOLITE BUSINESS OPPORTUNITIES

The Weholite family meets on a regular basis at seminars and working groups to share ideas, promote business expansion and explore opportunities for joint working. The Weholite concept is a fantastic base for pre-fabrications of all kinds and is open to new product ideas from licensees that require a quality, durable, environmentally friendly and economical solution.

- Weholite HDPE pipe available in sizes up to 3.5m diameter

- Full business support offered, including training and marketing

- A wide variety of applications

- Access to a global network of manufacturers

- 36 production lines globally

- Wehopanel manufacturing for rectangular applications

JOIN THE WEHOLITE FAMILY. More information ANDERS.NYSTRAND@UPONOR.COM